|

|

OUR COMMITMENT

Creating Safe Workplaces and Protecting Our Resources

Sustainability is about preserving the planet and reducing our environmental impact. At Polygroup®, we are committed to maintaining safe, reliable, and environmentally responsible facility operations. To help prioritize our sustainability efforts, we are focusing on the areas where we can have the greatest impact and that have the greatest impact on our business: Energy, Air Quality, Material Waste, and Safety. Our goals are to:

•Reduce energy usage in all our facilities

•Reduce energy-related carbon dioxide emissions specifically with transportation and distribution

•Reduce packaging material with a focus on using more recycled components

•Reduce, reuse, and recycle production materials such as PVC, PE, steel, and paper

•Prevent work related injuries and illnesses

Our concern with both the environment and employee welfare in maintaining safe sustainability practices has been part of our business strategy for many years. At Polygroup®, we recognize that we must continue to implement projects that reduce waste and develop "Green Engineering" technologies to create new environmentally friendly materials. We are also focusing on programs such as worker safety education and routine physical checkups to protect the health and safety of our employees.

Our goal is to reduce pollution by encouraging sustainable practices of the resources we use and to maintain compliance with all regulations in providing quality products for our clients. By making sustainability part of every business decision, we are making a conscious effort to reduce our company's production waste and carbon footprint on the world. Our focus on conservation ensures that we can make a difference for our future generations.

REDUCING WASTE

Reduce, Reuse, Recycle

Polygroup® recognizes the importance of efficient and responsible production systems designed to promote sustainability practices in our company. We constantly monitor the way our business operates to better understand the effect our operations have on the world around us. At the moment, the four types of raw materials used in largest quantities in our manufacturing plants are PVC (Polyvinyl Chloride), PE (Polyethylene), steel, and paper. Despite rigorous efforts, waste and defective materials from production lines are unavoidable. Since 2001, Polygroup® has set up stringent reduce, reuse, and recycling programs and integrated them into the manufacturing process.

PVC (Polyvinyl Chloride)

PVC is the largest amount of raw material purchased for use in our manufacturing facilities. Rigid PVC resin is used in Christmas tree production, and soft PVC resin is used in pools and inflatable toys. Wasted PVC film and defective tree tips and pool components are shredded into a very fine grain and then melted down into PVC pellets for future use. Since the quality of recycled PVC is lower than virgin PVC, recycled PVC is unsuitable for use in producing Christmas tree tips, pools, and inflatable toys. However, recycled PVC can be used in other components that are necessary for production. Examples include plastic tree stands for our Christmas trees and light sockets used in the light strings on prelit trees. Additional applications for recycled PVC include protective covers for raw materials and finished products and plastic baskets for transporting goods.

PE (Polyethylene)

Recently, PE has become a popular alternative to PVC in making Christmas trees. At Polygroup®, waste from PE tree tip manufacturing is gathered, melted down, and reused in the form of plastic bags for packaging replacement parts and as bubble wrap to protect finished products.

Steel

Aside from plastics, large quantities of steel are required for the production of Polygroup®'s products. These include components such as support poles for frame pools, metal tree stands, tree hinges, and wire for tree tips and branches. At this time, Polygroup® does not have the facilities to recycle steel in our plants. Nevertheless, Polygroup® is committed to recycling all salvageable manufacturing waste including those that we cannot recycle on-site such as steel. As a result, Polygroup® has contracted a third party to recycle all steel waste gathered from production lines.

Paper

Since all of our products require packaging for shipment, Polygroup® is focused on reducing the amount of packaging needed and replacing packaging materials with recycled components. As part of our vertically integrated manufacturing system, we produce our own cardboard packaging with at least 25% recycled content, and all discarded boxes and paper waste are recycled. Using recycled cardboard boxes in combination with bubble wrap recycled from PE, Polygroup® continues to make every effort in becoming more environmentally friendly.

Making Steady Progress

Since the initiation of these reuse and recycling programs in 2001, Polygroup® has consistently recycled a significant amount of the wasted PVC and PE. In 2007, over 6,000 metric tons were recycled and reused. This represents 14% of the total amount consumed during manufacturing. In addition, all 6% of wasted steel was outsourced and recycled. In total combined, Polygroup®'s recycling system reused over 9,000 metric tons of material during the production year that would otherwise be deposited in landfills.

Reducing, reusing and recycling PVC, PE, steel, and paper is only one of the goals that Polygroup® has established for our environmental sustainability efforts. Polygroup® will continue to provide the very best products to our clients while maintaining compliance with all environmental regulations and policies.

QUICK FACTS

Did you know?

Have a question about our raw materials and their uses in our products? Concerned about our product's safety? Below are some quick facts that may help answer your questions.

What is PVC?

Polyvinyl chloride (PVC) was first manufactured in Germany in 1931 as a durable and lightweight new plastic. PVC was introduced as a substitute for metals, glass, wood, natural fibers, papers, and fabrics.

As a raw material, PVC has many applications in today's world. PVC is used in water and sewage pipes and electrical lines. In housing, PVC can be found in sidings, flooring, and furniture. Agricultural and industrial purposes include green house coverings, tents, automobile parts, and electrical appliances. Consumer products include food wraps, synthetic leather, and stationary. Medical applications include IV bags, tubing, and packaging for medications.

PVC is the plastic of choice for many applications due to its cost efficiency, durability, fire-resistant properties, and natural resources-saving features.

Is PVC used for artificial trees and pools safe?

The misconception that PVC is harmful to humans may stem from the fact that PVC is produced from the raw material Vinyl Chloride Monomer (VCM), which is a high-pressure gas that can pose risks to human health due to its carcinogenicity. However, PVC is manufactured and processed under strict controls for safety and once produced it is an entirely new product that is chemically and mechanically stable and does not affect human health. PVC is a safe plastic under normal conditions of use. The International Agency for Research on Cancer (IARC), which is a branch of the World Health Organization (WHO), classified PVC as Group 3 (Not classifiable as to its carcinogenicity in humans), alongside caffeine, chlorinated drinking water, and tea.

How is PVC an environmentally beneficial plastic?

PVC requires only about 70% of energy needed for production when compared to other plastics. This means less carbon dioxide emissions; therefore, it is more environmentally friendly in preventing global warming. PVC also has excellent recyclable properties. Recovered products can easily be reconverted to other products. The physical properties of these recycled products are almost the same as with products made from virgin resin, and these second-life products continue to exhibit the same durability and strength. PVC recycling will continue to be extremely important as the world continues to focus on sustainability by reducing, reusing, and recycling waste.

CHRISTMAS RECYCLING PROGRAM

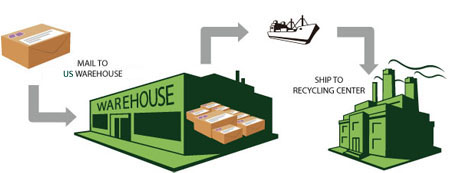

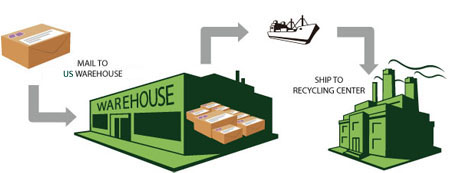

Don't want to throw your old Christmas lights, extension cords, and artificial trees in the trash? Send them to us, and we will recycle them for you. Here is how it works:

What do we do with the lights and trees?

When we receive your lights, extension cords, and trees for recycling, we will remove them from the package and recycle the box. We will then ship the products in bulk to our in-house recycling facility located in Dongguan, China. Our recycling center will sort the products and process the lights and trees through a commercial shredder to break them down to smaller pieces. These pieces are then further processed, filtered, and sorted into the various components that make up the lights and trees(eg. PVC, copper, and metal). These materials will then be re-used for second generation products such as bubble wrap and plastic bags.

Why should I participate in the program?

Be a responsible consumer, and help protect the environment by reducing landfill waste.

Where should I send my used lights and trees for recycling?

Recycling Center

651 S. Stratford, Suite 100

Meridian, ID 83642

Please DO:

1. Pack your lights and trees in cardboard boxes or other packaging that can be

easily recycled.

2. Pack items as tightly and compactly as possible to reduce size of packaging.

3. Coordinate with your friends, neighbors, co-workers, social groups, church

groups, or other organizations when possible to collect lights and trees and

send in one bulk shipment. This will help reduce shipping costs for everyone

and reduce the environmental impact of shipping.

Please DO NOT:

1. Include any packing material or anything other than the lights, extension

cords, and trees themselves.

2. Put your lights, extension cords, and trees in plastic bags or any other interior

packaging.

Thank you for visiting our website and for participating in Polygroup®’s recycling program. Please feel free to contact us should you have any questions.

|

|

|

| |

|

About Us |

Products |

How To |

Sustainability |

Support |

Careers |

|

| |

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|